plug flow reactor solved problems pdf

A short summary of this paper. Even today as the quantity of industrial effluents discharged is on the increase and the types of pollutants present in the effluent streams are getting diversified wastewater treatment processes are being investigated and experimented exorbitantly all over the globe.

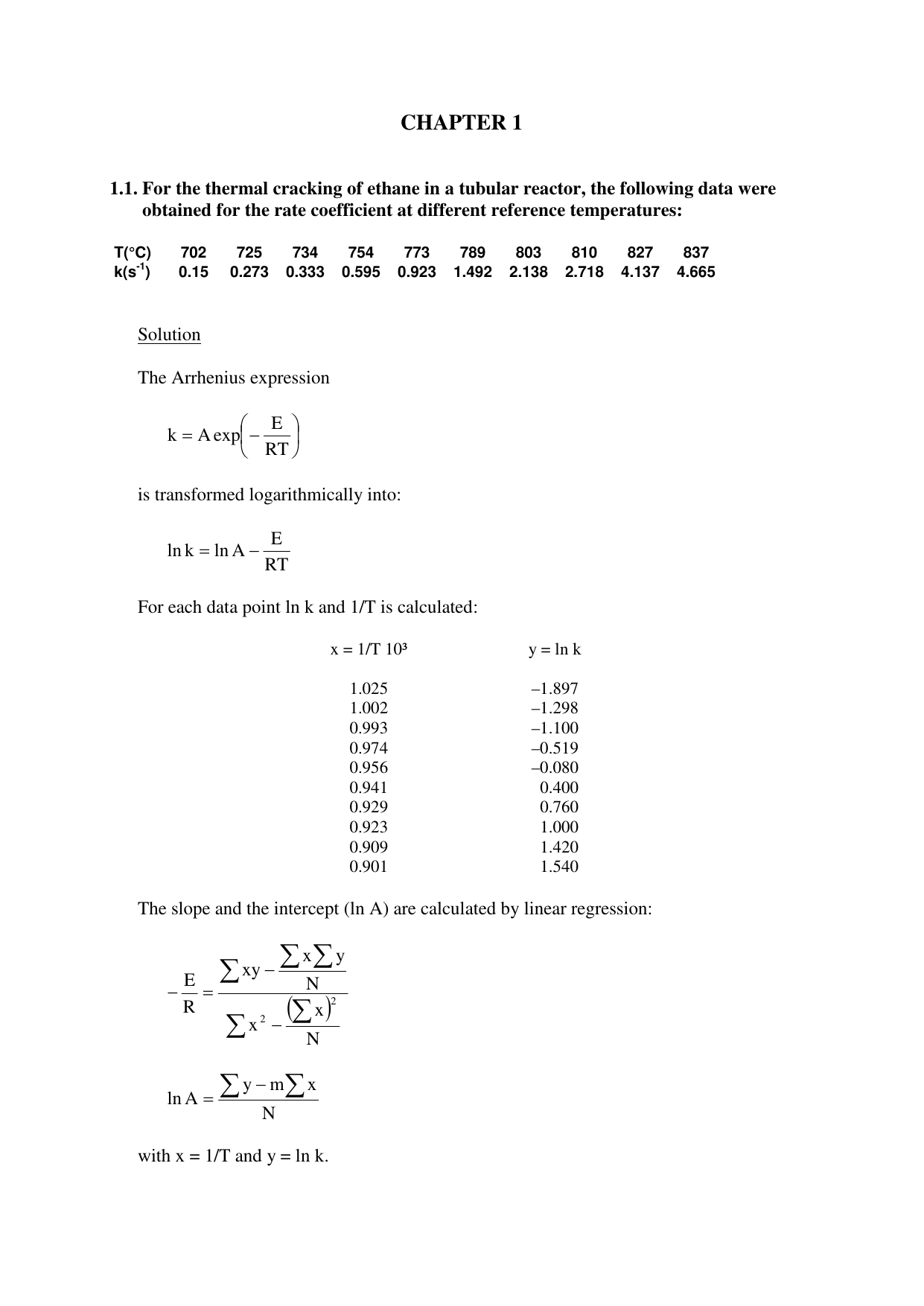

Solution Manual To Chemical Reactor Analysis And Design

Download Full PDF Package.

. A biological methanation plant requires a reactor several orders of magnitude larger to convert a certain feed gas flow compared with an adiabatic fixed-bed reactor. Solucionario de Chapra y Canale Quinta Edicion. Anaerobic digestion is a sequence of processes by which microorganisms break down biodegradable material in the absence of oxygen.

Much of the fermentation used industrially to produce food and drink products as well as home fermentation uses anaerobic digestion. The plug flow reactor is a rectangular nonfully mixed reactor. 33 Full PDFs related to this paper.

Download Full PDF Package. Flow dynamics were simulated in a virtual reactor with similar dimensions and operating conditions as the one used in the experimental part to illustrate the enhanced mixing provided by the oscillating flow. Baffles are set in half of the reactor at a set inclinate so that the material.

The results demonstrate that the pulses of the oscillating conditions significantly enhance the mixing of the flow thus improving the contact of the fluid. Solucionario de Chapra y Canale Quinta Edicion. A high concentration of solid or semisolid fermentation raw material enters from one end of the feed inlet and then will be discharged from the other end after supplementation.

In principle there are two main reactor types for continuous processing. The process is used for industrial or domestic purposes to manage waste or to produce fuels. The majority of the discussed reactor designs that used PFA FEP and glass tubes or capillaries are examples of the PFR-type reactors chosen due to their excellent residence time control and.

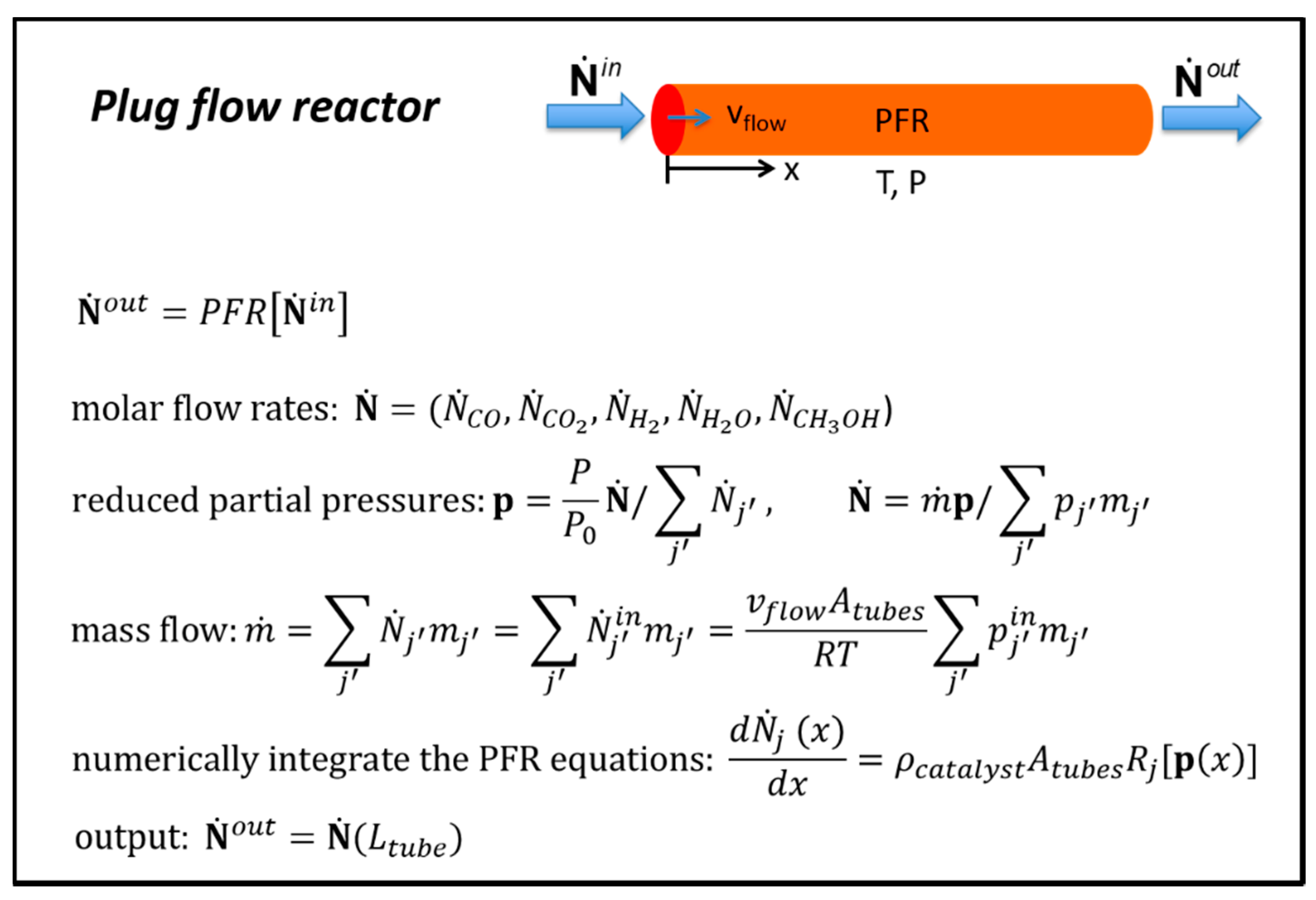

17 Full PDFs related to this paper. The CSTR continuous stirred-tank reactor and the PFR plug flow reactor both schematically shown in Figure 15. The maximum GHSV of 100 h 1 for the biological methanation in combination with a methane content of 90 is an optimistic value which based on the published results was not yet reached see section.

Full PDF Package Download Full PDF Package. A short summary of this paper. 141 Plug flow reactor.

Biological wastewater treatment is a biochemical process that is centuries old. Full PDF Package Download Full PDF Package. Chemical Reaction Engineering 3rd Edition by Octave Levenspiel.

Lecture 19 Plug Flow Reactor Design Ppt Plug Flow Reactor Design Material Balances On A Pfr A A A B B P B V Al 0 Z P L Z We Course Hero

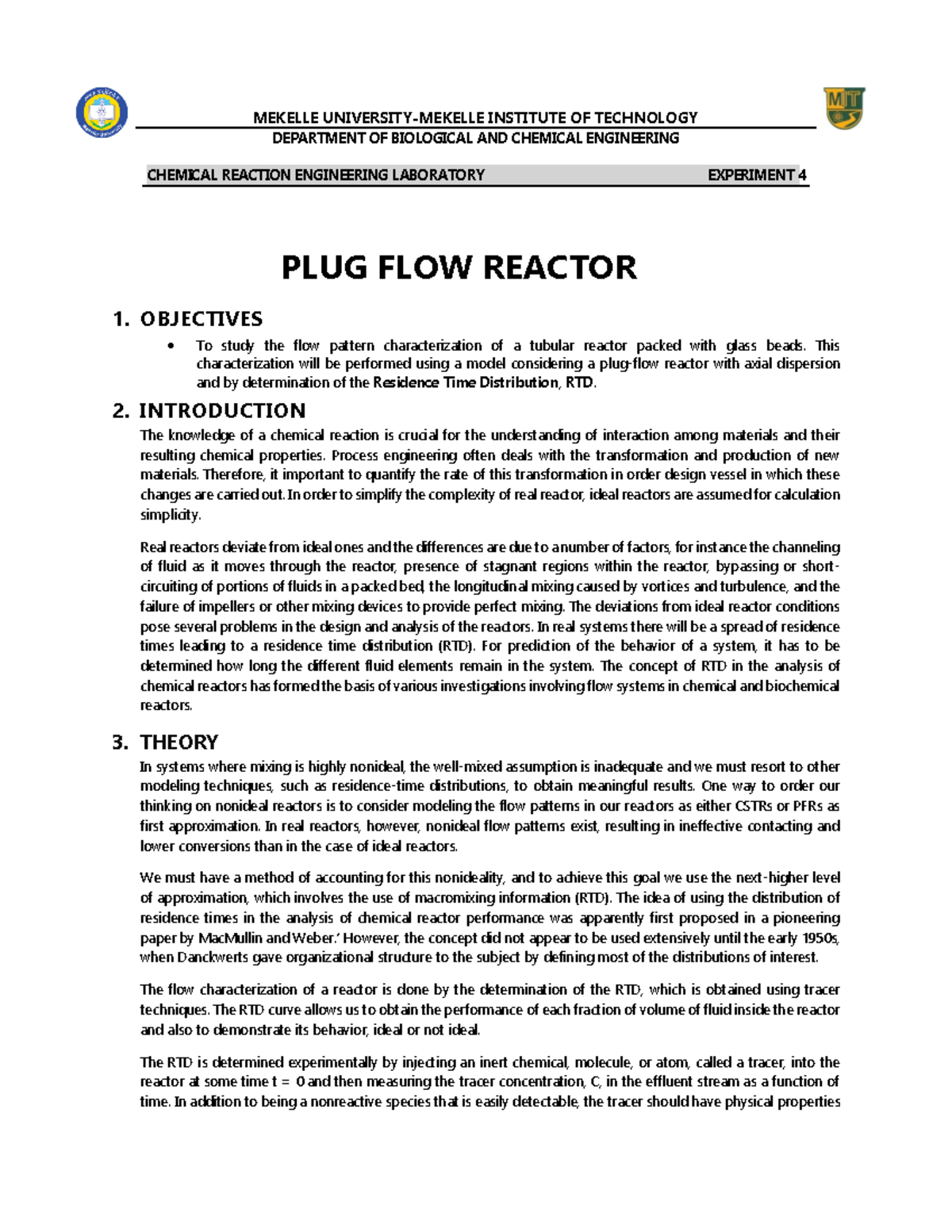

Rtd Pfr Step Input Done Mekelle Institute Of Technology Department Of Biological And Chemical Studocu

Chemical Reactors Problems Of Plug Flow Reactor 23 35 4c2h2

Pdf Plug Flow Reactor Model Wikipedia The Free Encyclopedia Praveenkumar Dtv Academia Edu

Chemengineering Free Full Text Understanding Catalysis A Simplified Simulation Of Catalytic Reactors For Co2 Reduction Html

Pdf Solution Manual Essentials Of Chemical Reaction Engineering Juan Manuel Garcia Ayala Academia Edu

Pdf A Plug Flow Reactor For Studying Fuel Autoignition Chemistry At Pressures Of Up To 50 Bar